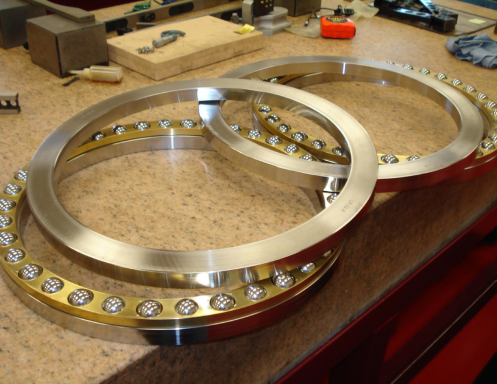

Bearing Reconditioning Service

WHY RECLAIM YOUR BEARINGS?

A reconditioned bearing can cost 20- 80 percent less than a new bearing. In some cases, a bearing can be reconditioned multiple times to improve service life and further reduce operating costs.

Bearing maintenance and reconditioning services do more than make your bearing look nicer. In fact, reconditioning refreshes the inner rolling geometry of your bearings and keeps minor etching, denting and surface blemishes from propagating into major, unrepairable fatigue damage. Reconditioning restores life to your roller bearings and keeps them running longer.

MAIN BENEFITS OF BEARING REPAIR SERVICES

•Maximized bearing life

•Fraction of the cost of a new bearing

•Faster turnaround than the typical lead time for a new bearing

•Multiple options and levels of repair to meet many needs and budgets.

HOW IT WORKS

Send your bearing to Acurtech when it is taken out of service. Our highly skilled bearing specialists rigorously inspect each bearing assembly. Internal rolling elements are inspected visually and dimensionally, exceeding OEM bearing manufacturer specifications for geometry, roundness and surface finish.

The reconditioned bearing is sent back to you and placed into a spares inventory. When the next bearing is removed, the reconditioned bearing can be installed immediately. This avoids costly downtime from waiting for out-of-stock

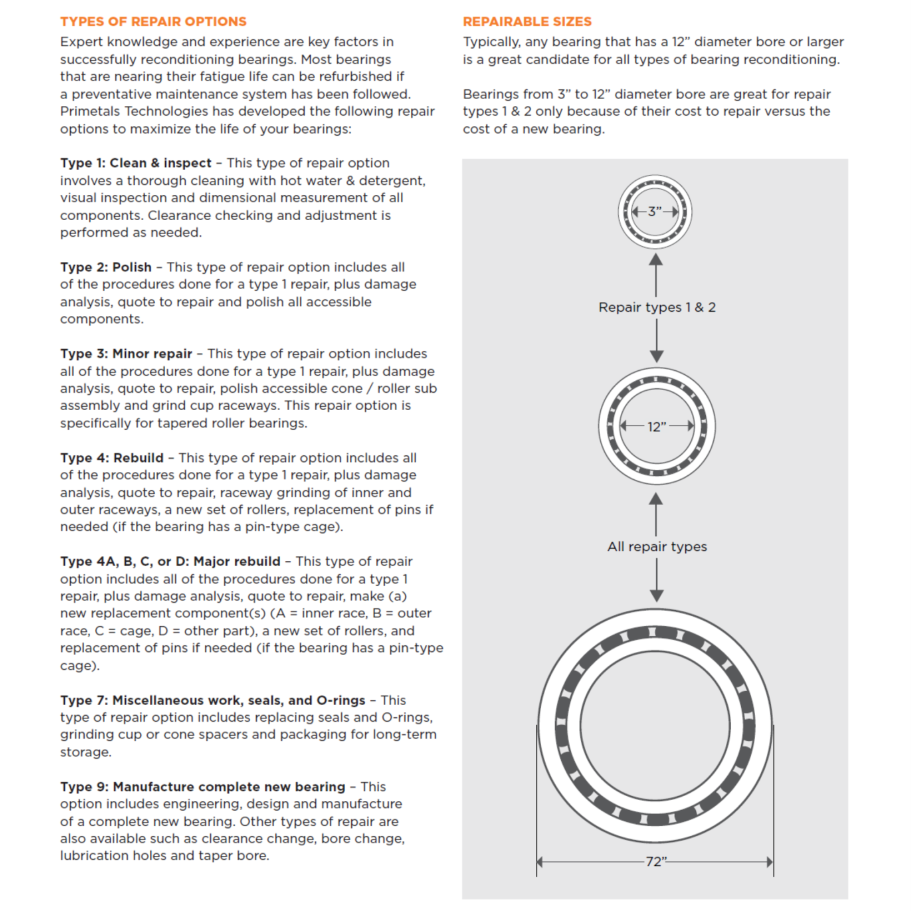

parts. Send the used bearing to Acurtech bearing shop and the cycle repeats.